Airline Operations Solutions, Inc. a Texas Corporation since 2004

DBA Airopsol

Copyright © 2025. All rights reserved. Designed By – ADMark Digital Media

Copyright © 2025. All rights reserved. Designed By – ADMark Digital Media

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This 2005 AGIFORS presentation introduces Boeing’s ValSim (Value Simulator), a simulation and visualization tool developed to analyze the full ripple effect of airline delays. It quantifies how disruptions—particularly maintenance-related ones—escalate into system-wide inefficiencies. The tool models both “as-is” and “what-if” schedules, assigning specific delays and tracking consequences across functions. Findings reveal that while maintenance events are only ~9% of delay causes, they account for up to 30% of delay minutes due to longer durations and cascading effects. ValSim enables airlines to better forecast costs, reallocate resources, and improve schedule resilience.

This 1992 study by American Airlines and Flight Dynamics, Inc. delivers one of the earliest comprehensive assessments of the operational and financial impacts of weather-related diversions and irregular operations. By analyzing case studies at LGA and DFW, the team estimated the per-diversion cost at over $120,000—including hard costs, soft costs, and passenger ill-will losses. The report highlights the cascading effects of diversions across the network, especially at hub airports, and advocates for mitigation strategies such as the Heads-Up Display (HUD), the “Dump Plan,” and advanced decision-support systems to reduce both the frequency and severity of disruptions.

Developed by Mike Irrgang in 1991 at American Airlines, the “Dump Plan” proposes a radical shift in managing weather-related irregular operations at major hubs like DFW and ORD. Rather than holding or diverting flights reactively, the plan preemptively lands inbound aircraft at first-tier alternate airports before reaching the hub. This preserves complex sequencing, reduces fuel burn, minimizes gate congestion, and cuts crew and passenger misconnects. Though never fully implemented, simulations and partial tests showed strong potential for reducing disruption recovery time, flight cancellations, and operational costs, while enhancing predictability, safety, and passenger goodwill.

This presentation from the 2007 AGIFORS Operations Control conference by Kaaren Cramer and Michael Irrgang of Boeing Commercial Airplanes introduces a new methodology for costing airline disruptions. It moves beyond traditional average delay costs to a more nuanced approach that recognizes the accelerating cost of delays as their length increases. The methodology incorporates various cost categories, including direct passenger costs, direct operating costs, and the loss of aircraft availability, and also considers the impact of customer disloyalty. The presentation emphasizes that maintenance and engineering (M&E) delays are the primary drivers of long and costly disruptions.

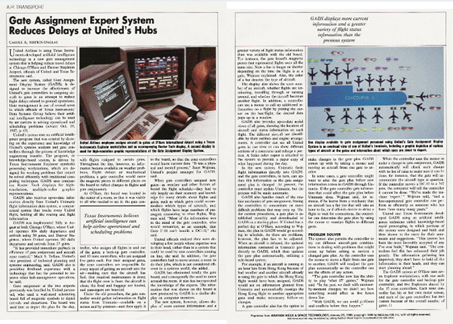

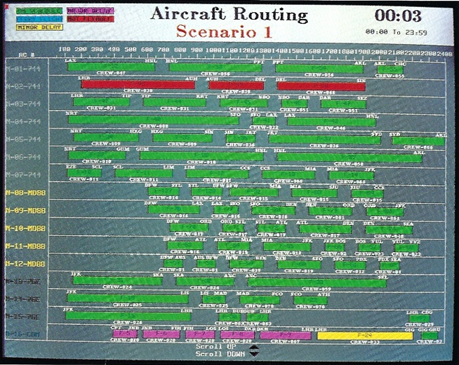

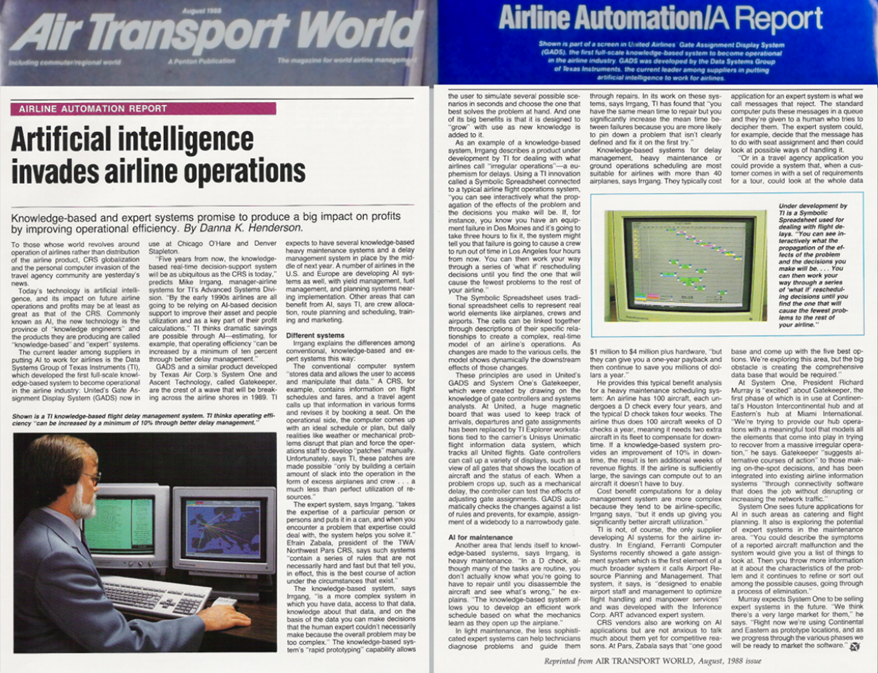

In 1985 Mike Irrgang led the development of the first airport gate assignment system, which was implemented at United Airlines at ORD and DEN.

Jl. Raya Renon No. 88, Bali 80571

Mon - Sat 08:00 AM - 20:00 PM